Part 5: Hauling Machines

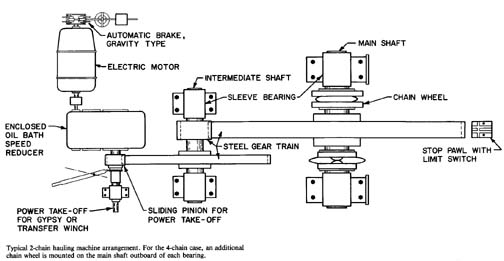

Hauling machines for railway dry docks have been developed for this particular use. A machine consists of a train of gears, now operated by electric motors but earlier using steam, turning one or more toothed chain wheels driving the hauling chain.

Each hauling chain is arranged, in conjunction with a smaller “backing chain,” in an endless system attached to the cradle. The hauling chain passes around its chain wheel, and the backing chain passes through a submerged sheave.

Enclosed oil-bath speed reducers are used to eliminate unnecessary noise and the danger of open high-speed gears, and to insure adequate lubrication with maximum cleanliness. Automatic brakes protect against cradles running away because of human or electrical failure. Interlocks are provided to prevent operating in reverse against the stop pawl or forward with the cradle against a head wall; their function is extremely important, since gear damage could result that would put the railway out of operation for several months.

Sometimes a railway dry dock cradle will surge during the hauling operation. Assuming a roller system in good condition and proper support for hauling chain, the surging can usually be eliminated by a moderate increase of the hauling speed. Naturally the increased speed will require greater horsepower, but it will also reduce the hauling and lowering times.

Years ago steam served as motive power, offering the advantages of true autonomy and a wide range of speeds. The switch to electricity – for new installations and by conversion of old ones – permitted the use of electric brakes, limit switches, and overload protection, and eliminated the need to fire boilers prior to operation.