Part 3: Side Haul Railway Dry Docks

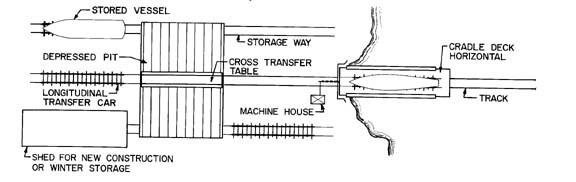

Longitudinal haul with side transfer

The side-haul railway is selected when required by conditions peculiar to many rivers – rivers often subject to wide ranges of water level, with periods of low water lasting several months, interspersed with shorter periods of high water. The vessels plying such rivers are of necessity shallow-draft, flat-bottomed craft of light construction, which may have to be drydocked at any river stage. To meet the requirements, side-haul railway dry docks are constructed on relatively steep gradients providing sufficient vertical movement to permit drydocking at all stages. Since they have certain inherent disadvantages, are comparatively expensive, and are not particularly well adapted for ocean-going vessels, they should be chosen only after careful study indicates that other types are unsuitable.

The principal technical disadvantage of the usual side-haul dock consisting of several cradles, each handled by one or two parts of chain or wire rope, is that the load on any part cannot be adequately determined, so that it is fundamentally impossible to use an equalizing system. In consequence it is necessary to use oversize chains or wire ropes to allow for possible overload.

The 300-ton dock designed for the French government and installed at Dordrecht, Holland, after World War II, was designed with a single, unitary cradle, using only two hauling chains. By this means, the load on each chain can be readily determined, and no differential movement of the chains can affect the load on them.

That railway, which has a transfer system, was installed to permit production-line erection of prefabricated Rhine barges supplied from the United States and Canada. It is useful in the longer run for docking these craft, with the transfer system available for those requiring extensive repair.