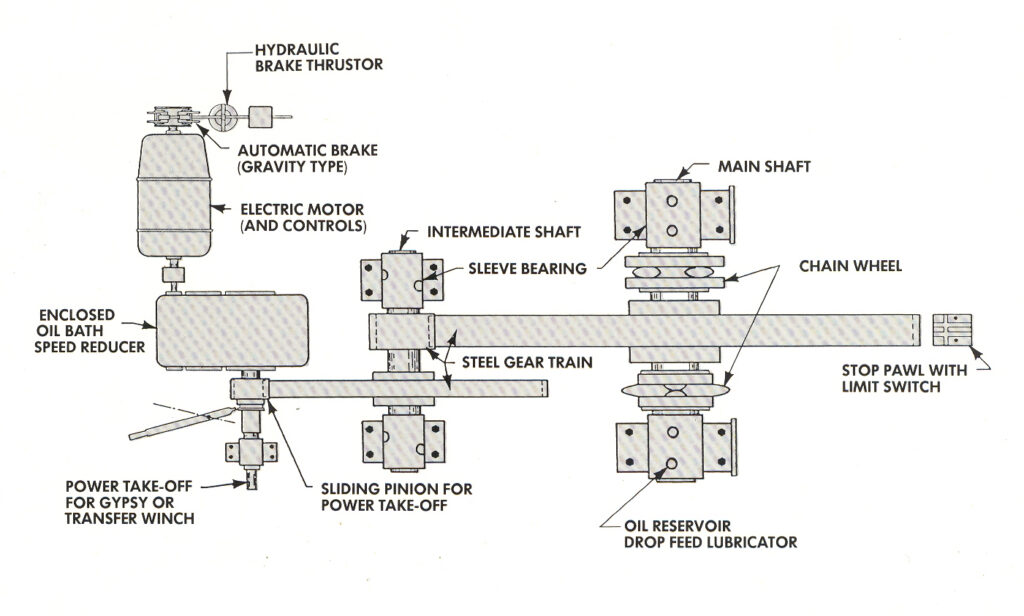

Crandall hauling machinery for a new or rebuilt railway dry dock generally consists of the components illustrated in the diagram shown above. An entire machine package can be custom designed or selected to accommodate existing conditions such as a particular chain size, number of chains (single, two, four or six), hauling speed, and space limitations. We are available to quote on developing and supplying a complete hauling machine assembly to suit your needs, including foundation details for its installation. Crandall also supplies individual components such as chain wheels, bearings, gears, pinions, reduction units, motors and controls which may be suitable as substitute parts for existing machines.

Crandall chain wheels are cast from high strength alloyed steel, heat-treated and ground to template to fit Crandall open-link hauling chains.

Our wheels have four, five and, in special cases, six teeth (or sides). They are designated as eight, ten and twelve-link wheels, since one revolution of a chain wheel results in chain movement equal to twice the number of teeth on the wheel.

Crandall chain wheels provide a positive hold on the chain at all times and have excellent wearability due to their hardness.

Crandall can furnish wheels ground to template; completely machined to accept existing shaft dimensions, or as rough unfinished castings for in-house machining.

Capacity Increase

Occasionally, shipyards ask if it is possible to increase the capacity of their existing railway dry dock. Quite often, this can be easily accomplished at a minimal cost by one of the following methods:

– Increase the chain size and substitute eight-link chain wheels for ten-link chain wheels.

– Use special short pitch hauling chain one size larger on the existing chain wheels.

– Replace existing iron gears with steel gears having a greater ratio to accommodate heavier chain wheels and chain.

Electrification of Old Machines

The reliability of modern electric motors and their ability to tolerate overload in many cases makes them most desirable for hauling ships out of the water. We can supply wound rotor motors, complete with controls, to suit your needs for new installations or for upgrading of existing docks. This may involve some gearing change in cases where the motor speed far exceeds that of the steam or other existing power source. The size and horsepower of the motor depend on the load, the gradient and hauling speed desired. Normally, we try to achieve one vertical foot of lift per minute. Inquiries regarding electrification should indicate all the characteristics of the power available at the site (i.e., voltage, KVA, phase and cycle), plus data on the machine gearing and sprocket size. Generally, motors are provided with automatic brakes mounted on the motor shaft extension.